Please choose online customer service:

What are the Product Standards for High-Voltage Inductors?

I. Introduction

High-voltage inductors are critical components in various electrical systems, playing a vital role in energy storage, filtering, and voltage regulation. As the demand for reliable and efficient electrical devices continues to grow, the importance of adhering to product standards for these inductors cannot be overstated. Product standards ensure that high-voltage inductors are safe, reliable, and compatible with other components in electrical systems. This blog post will explore the significance of product standards for high-voltage inductors, the key standards that govern their design and testing, and the challenges and future trends in this field.

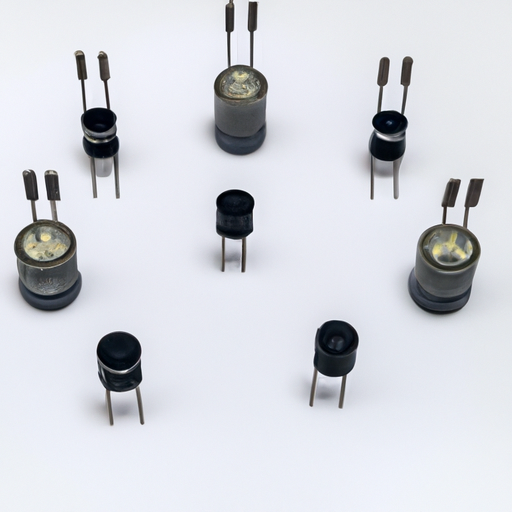

II. Understanding High-Voltage Inductors

A. Basic Principles of Inductors

Inductors are passive electrical components that store energy in a magnetic field when electrical current flows through them. The primary characteristic of an inductor is its inductance, measured in henries (H), which indicates its ability to store energy. Inductors are essential in various electrical circuits, where they help manage current flow, filter signals, and stabilize voltage levels.

B. Characteristics of High-Voltage Inductors

High-voltage inductors are designed to operate at elevated voltage levels, typically above 1,000 volts. Key characteristics include:

1. **Voltage Ratings**: High-voltage inductors must be rated to handle specific voltage levels without breaking down or failing.

2. **Current Ratings**: These inductors also have current ratings that indicate the maximum current they can handle without overheating or sustaining damage.

3. **Inductance Values**: The inductance value is crucial for determining how the inductor will behave in a circuit, affecting its performance in filtering and energy storage applications.

C. Applications of High-Voltage Inductors

High-voltage inductors are used in various applications, including:

1. **Power Supplies**: They are integral to switching power supplies, where they help regulate voltage and current.

2. **Electric Vehicles**: In electric vehicles, high-voltage inductors are used in power conversion systems to manage energy flow.

3. **Renewable Energy Systems**: These inductors play a role in wind and solar energy systems, helping to convert and stabilize power output.

III. Importance of Product Standards

A. Ensuring Safety and Reliability

Product standards are essential for ensuring the safety and reliability of high-voltage inductors. By adhering to established standards, manufacturers can minimize the risk of failures that could lead to hazardous situations, such as electrical fires or equipment damage.

B. Facilitating Interoperability and Compatibility

Standards promote interoperability and compatibility among different components and systems. This is particularly important in complex electrical systems where various manufacturers' components must work together seamlessly.

C. Enhancing Performance and Efficiency

Compliance with product standards often leads to improved performance and efficiency. Standards provide guidelines for optimal design and testing practices, ensuring that inductors operate effectively within their specified parameters.

D. Regulatory Compliance and Market Access

Many markets require compliance with specific standards for products to be sold. Adhering to these standards not only ensures regulatory compliance but also enhances market access for manufacturers.

IV. Key Product Standards for High-Voltage Inductors

A. International Electrotechnical Commission (IEC) Standards

The IEC develops international standards for electrical and electronic technologies. Relevant IEC standards for high-voltage inductors include:

1. **IEC 60076**: This standard covers power transformers and includes guidelines for inductors used in transformer applications.

2. **IEC 61800**: This standard pertains to adjustable speed electrical power drive systems, which often utilize high-voltage inductors.

B. Institute of Electrical and Electronics Engineers (IEEE) Standards

The IEEE develops standards that are widely recognized in the electrical engineering community. Key IEEE standards applicable to inductors include:

1. **IEEE 112**: This standard provides methods for testing the efficiency of electrical machines, including inductors.

2. **IEEE 519**: This standard addresses harmonic distortion in power systems, which is relevant for inductors used in filtering applications.

C. Underwriters Laboratories (UL) Standards

UL is a global safety certification organization that develops standards for electrical components. The UL certification process for inductors involves rigorous testing to ensure safety and performance. Key UL standards for high-voltage applications include:

1. **UL 1410**: This standard covers the safety of inductors and transformers used in high-voltage applications.

2. **UL 60950**: This standard pertains to the safety of information technology equipment, which may include inductors in power supply systems.

D. Other Relevant Standards

In addition to IEC, IEEE, and UL standards, other organizations also contribute to the development of product standards for high-voltage inductors:

1. **American National Standards Institute (ANSI)**: ANSI develops standards that promote safety and efficiency in electrical components.

2. **European Committee for Electrotechnical Standardization (CENELEC)**: CENELEC establishes standards for electrical equipment in Europe, including inductors.

3. **National Electrical Manufacturers Association (NEMA)**: NEMA develops standards that address the performance and safety of electrical products, including inductors.

V. Testing and Quality Assurance

A. Testing Methods for High-Voltage Inductors

To ensure compliance with product standards, high-voltage inductors undergo various testing methods, including:

1. **Electrical Testing**: This includes tests for insulation resistance, dielectric strength, and inductance measurements.

2. **Thermal Testing**: Thermal testing evaluates the inductor's performance under different temperature conditions to ensure it can operate safely without overheating.

3. **Mechanical Testing**: Mechanical tests assess the inductor's durability and resistance to physical stress, including vibration and shock.

B. Quality Assurance Processes

Quality assurance is critical in the manufacturing of high-voltage inductors. Key processes include:

1. **Manufacturing Quality Control**: Implementing strict quality control measures during production to ensure that each inductor meets specified standards.

2. **Compliance Verification**: Regular audits and inspections to verify compliance with relevant standards and regulations.

3. **Continuous Improvement Practices**: Adopting practices that promote ongoing improvements in manufacturing processes and product quality.

VI. Challenges in Meeting Product Standards

A. Technological Advancements and Evolving Standards

As technology advances, product standards must evolve to keep pace. Manufacturers face challenges in adapting to new standards while maintaining product performance and safety.

B. Cost Implications of Compliance

Compliance with product standards can be costly, particularly for small manufacturers. The expenses associated with testing, certification, and quality assurance can pose significant challenges.

C. Balancing Performance with Regulatory Requirements

Manufacturers must balance the need for high performance with the requirements of regulatory compliance. This can be particularly challenging in high-voltage applications where performance demands are high.

VII. Future Trends in High-Voltage Inductor Standards

A. Emerging Technologies and Their Impact on Standards

Emerging technologies, such as electric vehicles and renewable energy systems, are driving changes in product standards for high-voltage inductors. As these technologies evolve, standards will need to adapt to address new challenges and requirements.

B. The Role of Sustainability in Product Standards

Sustainability is becoming increasingly important in product standards. Manufacturers are being encouraged to adopt environmentally friendly practices and materials in the production of high-voltage inductors.

C. Anticipated Changes in Regulatory Frameworks

As global markets continue to evolve, regulatory frameworks governing high-voltage inductors are likely to change. Manufacturers must stay informed about these changes to ensure ongoing compliance.

VIII. Conclusion

Product standards for high-voltage inductors are essential for ensuring safety, reliability, and performance in electrical systems. As technology advances and new applications emerge, the importance of compliance with these standards will only grow. Manufacturers must remain vigilant in their efforts to meet regulatory requirements while continuing to innovate and improve their products. The future of high-voltage inductor standards will be shaped by emerging technologies, sustainability considerations, and evolving regulatory frameworks, making it a dynamic and critical area of focus for the electrical engineering community.

IX. References

1. International Electrotechnical Commission (IEC) - [IEC Standards](https://www.iec.ch)

2. Institute of Electrical and Electronics Engineers (IEEE) - [IEEE Standards](https://www.ieee.org)

3. Underwriters Laboratories (UL) - [UL Standards](https://www.ul.com)

4. American National Standards Institute (ANSI) - [ANSI Standards](https://www.ansi.org)

5. European Committee for Electrotechnical Standardization (CENELEC) - [CENELEC Standards](https://www.cenelec.eu)

6. National Electrical Manufacturers Association (NEMA) - [NEMA Standards](https://www.nema.org)

This blog post provides a comprehensive overview of the product standards for high-voltage inductors, highlighting their importance, key standards, testing methods, and future trends. By understanding these aspects, manufacturers and engineers can ensure the safe and effective use of high-voltage inductors in various applications.