Please choose online customer service:

The Latest Inductor Knowledge: Procurement Models of Equipment Components

I. Introduction

Inductors are fundamental components in electronic circuits, playing a crucial role in energy storage, filtering, and signal processing. As the demand for electronic devices continues to rise, understanding the procurement models for equipment components, particularly inductors, becomes increasingly important. This article aims to explore various procurement models, their significance, and how they impact the sourcing of inductors and other equipment components.

II. Understanding Inductors

A. Basic Principles of Inductors

Inductors are passive electrical components that store energy in a magnetic field when electrical current flows through them. The basic function of an inductor is to resist changes in current, making them essential for various applications in electronic circuits.

1. Definition and Function

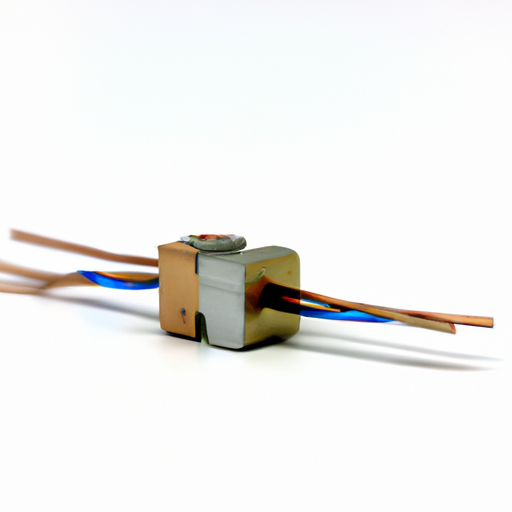

An inductor consists of a coil of wire, often wound around a core material, which can be air, iron, or ferrite. When current passes through the coil, a magnetic field is generated, which can store energy. This property is utilized in various applications, including filtering, energy storage, and voltage regulation.

2. Types of Inductors

Inductors come in several types, each suited for specific applications:

Air Core Inductors: These inductors do not use a magnetic core, making them suitable for high-frequency applications.

Iron Core Inductors: These inductors use iron as a core material, providing higher inductance values and better energy storage.

Toroidal Inductors: Shaped like a doughnut, these inductors minimize electromagnetic interference and are often used in power supplies.

B. Applications of Inductors in Electronic Devices

Inductors are widely used in various electronic devices, including:

1. Power Supplies

Inductors are essential in switching power supplies, where they help regulate voltage and current, ensuring stable operation.

2. Filters

Inductors are used in filters to block high-frequency signals while allowing low-frequency signals to pass, making them crucial in audio and communication systems.

3. Transformers

Inductors are integral to transformers, which transfer electrical energy between circuits through electromagnetic induction.

C. Importance of Selecting the Right Inductor

Choosing the appropriate inductor for a specific application is vital for ensuring optimal performance. Factors such as inductance value, current rating, and core material must be considered to meet the requirements of the circuit.

III. Procurement Models Overview

A. Definition of Procurement Models

Procurement models refer to the strategies and processes organizations use to acquire goods and services. In the context of equipment components, these models dictate how companies source inductors and other essential parts.

B. Importance of Procurement Models in the Supply Chain

Effective procurement models are crucial for maintaining a smooth supply chain. They help organizations manage costs, ensure quality, and minimize lead times, ultimately impacting the overall efficiency of production.

C. Factors Influencing Procurement Decisions

Several factors influence procurement decisions, including:

Cost: The price of inductors and other components can vary significantly based on supplier and market conditions.

Quality: Ensuring high-quality components is essential for the reliability of electronic devices.

Lead Time: The time it takes to receive components can affect production schedules and project timelines.

IV. Common Procurement Models for Equipment Components

A. Direct Procurement

1. Definition and Process

Direct procurement involves purchasing components directly from manufacturers or suppliers. This model is often used for high-volume purchases.

2. Advantages and Disadvantages

**Advantages**:

- Lower costs due to bulk purchasing.

- Direct communication with suppliers.

**Disadvantages**:

- Requires significant upfront investment.

- Risk of overstocking.

3. Examples in the Context of Inductors

For instance, a company manufacturing power supplies may engage in direct procurement of inductors to ensure a steady supply for production.

B. Indirect Procurement

1. Definition and Process

Indirect procurement refers to acquiring goods and services that are not directly related to the production process, such as office supplies or maintenance services.

2. Advantages and Disadvantages

**Advantages**:

- Flexibility in sourcing.

- Potential for cost savings through competitive bidding.

**Disadvantages**:

- Less control over quality.

- Longer lead times.

3. Examples in the Context of Inductors

While indirect procurement may not directly apply to inductors, it can encompass the sourcing of tools and equipment used in the manufacturing process.

C. Just-In-Time (JIT) Procurement

1. Definition and Principles

JIT procurement focuses on receiving goods only as they are needed in the production process, minimizing inventory costs.

2. Benefits and Challenges

**Benefits**:

- Reduced inventory holding costs.

- Increased efficiency in production.

**Challenges**:

- Risk of stockouts if suppliers cannot meet demand.

- Requires strong supplier relationships.

3. Application in Inductor Procurement

JIT procurement can be particularly beneficial for companies that require specific inductors for short production runs, allowing them to minimize excess inventory.

D. Bulk Procurement

1. Definition and Process

Bulk procurement involves purchasing large quantities of components at once, often to take advantage of lower prices.

2. Cost Benefits and Risks

**Cost Benefits**:

- Lower per-unit costs.

- Potential for better negotiation terms with suppliers.

**Risks**:

- Risk of obsolescence if components are not used quickly.

- Increased storage costs.

3. Relevance to Inductor Sourcing

Companies that manufacture electronic devices may engage in bulk procurement of inductors to ensure they have sufficient stock for production.

E. Strategic Sourcing

1. Definition and Methodology

Strategic sourcing is a comprehensive approach to procurement that focuses on long-term partnerships with suppliers to enhance quality and reduce costs.

2. Long-Term Partnerships and Supplier Relationships

Building strong relationships with suppliers can lead to better pricing, improved quality, and more reliable delivery.

3. Impact on Inductor Quality and Availability

Strategic sourcing can significantly enhance the quality and availability of inductors, ensuring that manufacturers have access to the best components for their products.

V. Emerging Trends in Procurement Models

A. Digital Transformation in Procurement

1. E-Procurement Systems

The rise of e-procurement systems has streamlined the procurement process, allowing companies to manage orders and suppliers more efficiently.

2. Data Analytics and Decision-Making

Data analytics tools enable organizations to make informed procurement decisions based on market trends and supplier performance.

B. Sustainability and Ethical Sourcing

1. Importance of Sustainable Practices

As environmental concerns grow, companies are increasingly prioritizing sustainable sourcing practices to minimize their ecological footprint.

2. Impact on Inductor Manufacturing and Procurement

Sustainable practices in inductor manufacturing can lead to more environmentally friendly products and improved supplier relationships.

C. Global Supply Chain Considerations

1. Geopolitical Factors Affecting Procurement

Geopolitical tensions can impact the availability and cost of components, making it essential for companies to diversify their supplier base.

2. Diversification of Suppliers

By diversifying suppliers, companies can mitigate risks associated with supply chain disruptions and ensure a steady flow of components.

VI. Challenges in Inductor Procurement

A. Supply Chain Disruptions

1. Causes and Effects

Supply chain disruptions can arise from various factors, including natural disasters, geopolitical tensions, and pandemics, leading to delays and increased costs.

2. Strategies for Mitigation

Companies can mitigate these risks by diversifying suppliers, maintaining safety stock, and developing contingency plans.

B. Quality Control Issues

1. Importance of Quality Assurance

Ensuring the quality of inductors is critical for the reliability of electronic devices. Poor-quality components can lead to device failures and increased warranty claims.

2. Methods for Ensuring Quality in Procurement

Implementing strict quality control measures, such as supplier audits and testing protocols, can help ensure that only high-quality inductors are sourced.

C. Cost Fluctuations

1. Factors Affecting Pricing

Pricing for inductors can fluctuate due to changes in raw material costs, demand, and market conditions.

2. Strategies for Managing Costs

Companies can manage costs by negotiating long-term contracts with suppliers, exploring alternative materials, and optimizing inventory levels.

VII. Best Practices for Effective Inductor Procurement

A. Conducting Market Research

1. Identifying Reliable Suppliers

Thorough market research can help companies identify reliable suppliers with a track record of quality and timely delivery.

2. Understanding Market Trends

Staying informed about market trends can help organizations anticipate changes in pricing and availability.

B. Building Strong Supplier Relationships

1. Importance of Communication and Collaboration

Open communication and collaboration with suppliers can lead to better pricing, improved quality, and more reliable delivery.

2. Long-Term Partnerships for Stability

Establishing long-term partnerships with suppliers can provide stability and reduce the risks associated with procurement.

C. Implementing Technology Solutions

1. Utilizing Procurement Software

Investing in procurement software can streamline the procurement process, making it easier to manage orders and suppliers.

2. Leveraging Data for Informed Decision-Making

Data analytics can provide valuable insights into supplier performance, market trends, and cost management, enabling organizations to make informed procurement decisions.

VIII. Conclusion

In conclusion, understanding the procurement models for inductors and other equipment components is essential for organizations in the electronics industry. By exploring various procurement strategies, companies can enhance their sourcing practices, improve quality, and manage costs effectively. As the industry continues to evolve, staying informed about emerging trends and best practices will be crucial for success in the competitive landscape of electronic component procurement.

IX. References

A comprehensive list of academic papers, articles, and resources for further reading on inductors and procurement models can be provided upon request. This will enable readers to deepen their understanding of the subject and stay updated on the latest developments in the field.